I’m thrilled to sit down with Zainab Hussain, an e-commerce strategist with a deep background in customer engagement and operations management. With her extensive experience in retail and process optimization, Zainab brings a unique perspective on how emerging technologies like generative AI are revolutionizing quality control in the consumer packaged goods and manufacturing sectors. Today, we’ll dive into the world of Certificate of Analysis (COA) processing, exploring the challenges of manual workflows, the limitations of traditional automation, and how innovative solutions are transforming efficiency and compliance.

How would you describe the role of a Certificate of Analysis in ensuring quality within the consumer packaged goods industry?

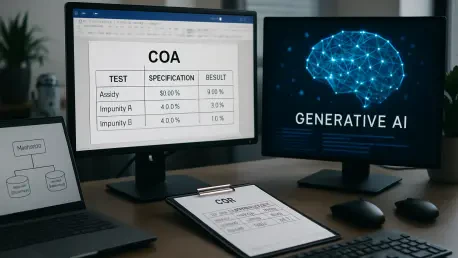

A Certificate of Analysis, or COA, is a vital document that certifies the quality and safety of a product batch before it’s accepted by a manufacturer. It’s essentially a supplier’s guarantee that their goods meet specific standards, which is critical in an industry where safety and regulatory compliance are non-negotiable. A COA typically includes details like test results, batch numbers, and sometimes chemical or physical properties of the product. It helps manufacturers confirm that what they’re receiving is safe for consumers and aligns with legal requirements, acting as a safeguard against potential risks or recalls.

What are some of the toughest hurdles companies face when they rely on manual processing for these COA documents?

Manual processing of COA documents is a real bottleneck for many companies. One of the biggest issues is the sheer variety of formats that suppliers use—there’s no universal standard, so each document might look completely different. This means staff have to spend hours deciphering and entering data by hand, which is prone to errors. On top of that, it slows down production significantly because shipments can’t be accepted until the COA is verified. This inefficiency can delay entire workflows, impacting everything from inventory management to delivery timelines.

Why do you think traditional automation tools have struggled to address the complexities of COA processing?

Traditional automation tools often fall short because they rely on rigid templates or custom-built AI models that need to be trained for each specific document format. This is incredibly time-consuming and expensive, especially when you’re dealing with hundreds of suppliers who might all present their COAs differently. Even worse, if a supplier suddenly changes their layout, the model becomes obsolete until it’s retrained. This lack of flexibility makes traditional approaches impractical for handling the dynamic and unstructured nature of COA documents.

Can you explain how generative AI solutions are changing the game for COA processing compared to older methods?

Generative AI solutions, unlike older automation tools, are built to handle variability without needing extensive pre-training for every format. They use advanced algorithms to intelligently classify, extract, and validate data from diverse COA layouts on the fly. This means they can adapt to new or unexpected formats with minimal setup. The result is a huge reduction in manual effort, allowing quality assurance teams to focus on decision-making rather than data entry, while still maintaining the accuracy needed for compliance.

What does the process look like for a company getting started with a generative AI tool for COA automation?

Getting started is surprisingly straightforward. First, a company would define what data they need to pull from their COA documents by creating a kind of blueprint in a user-friendly interface. This blueprint outlines key fields like batch numbers or test results. Then, they can upload a sample document to preview how the tool identifies and extracts the data, making adjustments as needed. The system often provides confidence scores for the extracted information, which helps decide if a human should double-check anything. It’s a flexible setup that doesn’t require deep technical expertise, making it accessible for operational teams.

I’ve heard about the concept of implicit fields in document processing. Can you shed light on what that means and why it’s valuable?

Implicit fields are a powerful feature. They refer to information that isn’t directly stated in the document but can be derived or calculated from the data that is there. For example, a generative AI tool might analyze multiple test results in a COA and determine if all values meet compliance rules, flagging the batch as compliant or not. This is incredibly useful for automating complex checks without needing to write intricate code or formulas. It saves time and ensures that subtle but critical insights aren’t missed during quality control.

How can a tool like this integrate into a company’s broader operational workflow for managing shipments?

Integration is where these tools really shine. Imagine a shipment arriving at a facility: the manager scans the COA document using a simple app, uploading it to the company’s cloud system. This upload triggers an automated workflow where the AI processes the document, extracts the necessary data, and checks for compliance. Based on the results, the system can notify the manager whether the shipment is cleared for unloading or needs further review. It’s seamless and lets staff focus on other tasks while ensuring nothing slips through the cracks.

What’s your forecast for the future of generative AI in quality control processes like COA processing?

I believe generative AI will become a cornerstone of quality control in industries like consumer packaged goods and manufacturing over the next few years. As these tools become more sophisticated, they’ll not only handle document processing but also predict potential compliance issues before they arise, using historical data and trends. We’ll see deeper integration with other systems, creating fully automated supply chains where human intervention is minimal. This will drive down costs, boost efficiency, and ultimately ensure higher standards of product safety in an increasingly complex market.