Our expert, Zainab Hussain, is a leading e-commerce strategist specializing in customer engagement and operations management. With extensive experience in the retail sector, she brings a sharp analytical eye to the latest corporate shake-ups and their impact on the supply chain. Today, she deciphers the recent leadership restructuring at J.M. Smucker Co., a move that consolidates vast operational responsibilities under a new Chief Product Supply Officer. The conversation will explore how this integrated structure aims to drive profitability, the strategic introduction of a Chief Technology Officer to spearhead an enterprise-wide AI initiative, and the challenges of managing a smooth transition amid significant executive departures.

Rob Ferguson’s new role combines vast supply chain oversight with strategic leadership for the coffee and pet food divisions. How will this integrated structure create new efficiencies, and what key performance indicators will you use to measure its success in driving profitability and margin expansion?

This is a classic and powerful move to break down internal silos. For years, companies have run supply chain and commercial teams as separate entities, which can feel like two different machines trying to work together. By placing procurement, distribution, and operations under the same leader who also has strategic P&L responsibility for coffee and pet, you create a single, unified engine. Imagine the friction this removes; a decision on commodity hedging can now be instantly weighed against its direct impact on coffee margins without a lengthy cross-departmental debate. Success will be measured by the numbers, pure and simple. We’ll be watching for an improvement in gross margin, a reduction in cost of goods sold, and faster inventory turnover. The fact that he also leads the company’s transformation office tells me they’re serious about tracking these metrics to drive that stated goal of profitability and earnings growth.

With two new senior VPs for operations and science set to report to the Chief Product Supply Officer, how is this new reporting structure intended to streamline decision-making? Could you walk us through how this might resolve a complex cross-departmental issue more effectively than before?

This new reporting line is all about creating a single point of accountability and accelerating the pace of innovation and execution. Previously, you might have had the head of R&D and the head of operations reporting to different executives, potentially even the COO and CEO. When a conflict arose, it had to be escalated, debated, and reconciled at the highest levels, which takes precious time. Let’s take a real-world scenario: suppose the science team develops a new, more sustainable packaging for pet food. In the old structure, the operations team might push back, citing increased costs or the need for new machinery. This could stall the project for months. Now, both SVPs report to Ferguson. He can sit them down in one room, look at the complete picture—the brand value of sustainability, the R&D investment, the operational costs—and make a decisive call that balances all factors. It transforms a potential bottleneck into a streamlined, strategic decision.

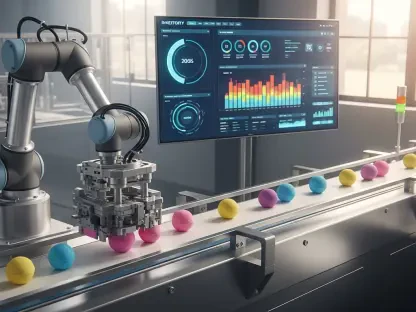

J.M. Smucker is establishing a new Chief Technology Officer role focused on advancing its enterprise AI strategy. In which areas—such as procurement, quality assurance, or distribution—do you foresee AI having the most immediate impact, and what are the first practical steps in implementing it?

The most immediate and tangible impact of AI will likely be felt in procurement and distribution. These are areas rich with data and complex variables, which is exactly where AI thrives. Think about commodity hedging for coffee beans; an AI model can analyze global weather patterns, political instability, and market trends far more effectively than any human team to optimize purchasing decisions. In distribution, it can revolutionize logistics by predicting demand spikes, optimizing delivery routes in real-time, and managing warehouse inventory to prevent stockouts. The first practical step for the new CTO will be to conduct an enterprise-wide data audit. You can’t have good AI without good data. They will need to identify clean, accessible data sets and then launch targeted pilot programs in these high-impact areas to demonstrate quick wins and build momentum for a broader rollout.

Given the departure of the COO and the retirement of two senior VPs in operations and supply chain, what is the strategy for ensuring a smooth transition and maintaining operational stability? Please share some details on how you will manage institutional knowledge transfer during this period.

Losing that much senior-level experience at once is a significant risk, and managing the transition is critical. The key is to avoid a knowledge vacuum. I would expect them to be heavily engaged in a structured knowledge transfer process right now, which involves more than just handing over a binder of notes. This means weeks of intensive shadowing, documented workflows, and most importantly, mapping the informal networks and decision-making processes that aren’t written down anywhere. For someone with 17 years of experience like Ferguson, he likely has a deep understanding of the organization’s history, but the departing SVPs hold decades of specific operational wisdom. The company will also lean heavily on the next layer of leadership—the directors and managers who worked directly under the retiring executives. Empowering them and ensuring they are part of the onboarding for the new SVPs will be essential for maintaining stability through this period of change.

What is your forecast for the consumer packaged goods supply chain over the next five years?

I foresee a dramatic acceleration toward what I call the “predictive supply chain.” The last few years have taught everyone that purely reactive models are too fragile. In the next five years, the winning CPG companies will be those that master predictive analytics and AI, not just as a tool but as the core of their operations. This means moving from simply fulfilling orders to accurately forecasting consumer demand at a hyper-local level, anticipating disruptions before they happen, and creating a truly resilient and agile network. We will see more automation in warehouses, greater visibility through blockchain, and a huge emphasis on sustainability as a non-negotiable component of supply chain design. The companies that successfully integrate technology to become more predictive, efficient, and transparent will not only survive, they will dominate the market.