The seamless promise of omnichannel retail often clashes with the harsh reality of inventory mismatches, creating a frustrating experience for both customers and staff alike. Radio-Frequency Identification (RFID) technology represents a significant advancement in bridging this gap between digital and physical stockrooms. This review will explore the evolution of the technology, its key features, performance metrics, and the impact it has had on various applications, particularly in the retail sector. The purpose of this review is to provide a thorough understanding of RFID’s current capabilities, its role in solving operational challenges, and its potential for future development.

Understanding RFID in Inventory Systems

RFID technology utilizes radio waves to read and capture information stored on a tag attached to an object. A tag can be read from up to several feet away and does not need to be within the direct line of sight of the reader to be tracked. This core principle allows for automated and highly efficient data capture, making it a transformative tool for inventory management compared to traditional barcode systems. Its relevance has grown exponentially with the rise of complex, fast-paced omnichannel retail environments.

This ability to capture data without direct line of sight fundamentally changes inventory processes. Unlike manual barcode scanning, which is labor-intensive and prone to error, RFID enables near-instantaneous bulk readings. A single pass of a reader can capture data from hundreds of tagged items, providing a complete and accurate snapshot of inventory in seconds. This level of speed and precision is critical for retailers who need to maintain accurate stock levels across multiple channels to meet customer expectations for availability and rapid fulfillment.

Key Technological Components and Processes

RFID Hardware Tags and Read Points

The physical backbone of any RFID system consists of two primary hardware elements: the tags and the readers. Tags are attached to individual inventory items and contain a microchip that stores a unique identifier. Readers, also known as read points, are strategically installed at key logistical locations, such as warehouse dispatch doors or store stockrooms. These devices emit radio waves that power the tags and capture their unique data, transmitting it for processing.

Modern RFID hardware emphasizes ease of integration. The plug-and-play nature of contemporary readers and antennas, as demonstrated in C&A’s recent deployment, allows for rapid and non-disruptive installation into existing infrastructure. This streamlined setup minimizes operational downtime and accelerates the time-to-value for retailers, making the technology more accessible than ever before. This approach removes significant barriers to adoption that once hindered widespread implementation.

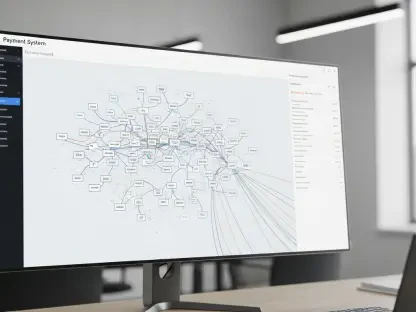

Centralized Inventory Engine Software

At the heart of an effective RFID deployment is the software platform that processes the immense volume of data collected from the readers. This centralized inventory engine, such as Nedap’s !D Cloud Inventory Engine, acts as the system’s brain. It receives raw data from thousands of tag reads and translates it into actionable business intelligence, providing a real-time, granular view of stock levels and locations across the entire supply chain.

The software’s primary function is to establish a single source of truth for inventory. By accurately tracking an item’s journey from the distribution center to the sales floor, it forms the foundation for reliable inventory accuracy. This real-time visibility is what empowers advanced retail strategies, ensuring that both store associates and e-commerce platforms are working with the same, up-to-the-minute stock information, which is crucial for preventing stockouts and overstocks.

Real-Time Status Assignment and Synchronization

A critical process enabled by a modern RFID system is the ability to automatically assign a specific status to an item as it moves through the supply chain. For instance, when an item destined for a Click & Collect order passes a dispatch read point at a warehouse, the system instantly updates its status to “reserved” or “in-transit.” This is a significant leap from simple presence detection; it adds contextual intelligence to each item’s data.

This status information is then synchronized in real time across all integrated platforms, from the enterprise resource planning (ERP) system to the point-of-sale (POS) terminals. This ensures that a reserved item is digitally excluded from the sellable inventory pool at the destination store, even before it physically arrives. Consequently, this prevents the common problem of reserved items being accidentally sold to in-store customers, thereby improving operational efficiency and safeguarding the customer experience.

Current Innovations in RFID Deployment

The latest developments in RFID deployment are focused on achieving a deeper integration with the complex demands of omnichannel retail. The prevailing trend is a strategic shift from using RFID for simple stock counting to employing it for sophisticated, status-based inventory management. This innovation allows retailers to digitally differentiate between various types of stock within a single physical location, such as distinguishing floor inventory from items awaiting pickup for Buy Online, Pick-up In-Store (BOPIS) orders.

This move toward status-based tracking directly supports a unified commerce model by ensuring data integrity across both digital and physical channels. By providing an accurate, real-time account of what is truly available for sale versus what is already allocated, retailers can confidently expose their entire inventory to online shoppers. This not only maximizes sales opportunities but also enhances the customer experience by preventing the disappointment that comes from ordering an item that is not actually available.

Application Spotlight The Retail Sector

C&A’s Strategic Omnichannel Enhancement

The European fashion retailer C&A provides a compelling case study on the strategic implementation of RFID to enhance its omnichannel capabilities. The company partnered with Nedap to deploy an RFID-based system to solve a key inefficiency in its widespread Click & Collect model. By implementing the technology in its e-commerce warehouses, C&A gained real-time visibility into items being shipped to stores for customer pickup, providing a robust technological foundation to support its growth.

This initiative was driven by the need to create a more cohesive and reliable shopping experience. Prior to the RFID implementation, discrepancies between digital and physical inventory led to operational challenges and potential customer dissatisfaction. The deployment, which became operational in late 2024, was designed not just as a technical upgrade but as a strategic move to ensure that C&A’s logistical infrastructure could effectively support its expanding omnichannel promises to consumers across Europe.

Optimizing the Click and Collect BOPIS Model

The core use case for C&A was to resolve the persistent issue of reserved online orders being mistakenly counted as regular store inventory during cycle counts. This common problem created a cascade of inaccuracies, leading to operational disruptions as staff would have to manually reconcile stock levels. The newly implemented RFID system addresses this head-on by automatically identifying and flagging these items as “reserved” the moment they leave the warehouse.

This simple yet powerful status change prevents reserved items from being sold to in-store customers and, just as importantly, digitally removes them from the store’s available stock count. This eliminates the need for manual checks and reconciliations, freeing up staff to focus on customer-facing activities. The result is a far more efficient BOPIS process, underpinned by inventory data that accurately reflects the real-world status of every single item.

Overcoming Operational Challenges

The primary challenge that modern RFID systems are engineered to address is persistent inventory inaccuracy, a problem that directly leads to lost sales from stockouts, increased costs from overstocks, and a degraded customer experience. In complex fulfillment models like BOPIS, this inaccuracy is magnified, as the line between different inventory pools becomes blurred. RFID mitigates this by providing a real-time, item-level view that minimizes both human error and data latency.

While the prospect of a large-scale technology implementation can be daunting, modern solutions are increasingly designed for rapid and minimally disruptive deployment. C&A’s project, for example, became fully operational within a matter of weeks, showcasing how providers are working to mitigate integration complexities through plug-and-play hardware and cloud-based software. This focus on ease of adoption is making RFID a more viable and attractive solution for a broader range of retailers.

Future Outlook and Scalability

The future of RFID in inventory management is rooted in its inherent scalability and its role as a cornerstone technology for unified commerce. Following the initial success of its warehouse deployment, retailers like C&A are already in the process of scaling the solution across their broader omnichannel infrastructure, extending its benefits to more stores and fulfillment channels. This illustrates a clear path from a targeted problem-solving tool to a foundational enterprise-wide platform.

Looking ahead, the next frontier will involve integrating the rich data stream from RFID systems with artificial intelligence and machine learning algorithms. This will unlock powerful capabilities for predictive analytics, more accurate demand forecasting, and further automation of supply chain decisions. Such advancements will enable an even more seamless and responsive connection between online and offline retail operations, allowing businesses to anticipate customer needs rather than just reacting to them.

Conclusion A Review of RFID’s Impact

RFID has proven to be a pivotal technology for modernizing inventory management, moving far beyond its initial perception as a simple replacement for the barcode. Its ability to deliver unparalleled levels of accuracy and real-time visibility directly addressed the core operational challenges that emerged with the rise of omnichannel retail. The successful implementation by C&A demonstrated that RFID was not just a tool for counting stock but a strategic asset for improving operational efficiency, reducing systemic disruptions, and ultimately enhancing the entire customer journey. The technology’s continued evolution and proven scalability signaled its long-term and transformative impact on the retail industry and its adjacent sectors.