Phoenix’s transformation from a sprawling desert metropolis into a global economic powerhouse is placing unprecedented strain on the logistics networks that are the lifeblood of its most critical industries. As the region’s growth accelerates, the intricate dance of moving high-value goods from airport tarmac to factory floor has become a high-stakes performance where a single misstep can trigger a cascade of costly disruptions. This new reality demands more than just faster trucks; it requires a fundamental reevaluation of how supply chains are designed to function under pressure. The city’s economic boom is not just a measure of success but also a test of operational resilience, and many businesses are discovering their traditional logistics models are ill-equipped for the challenge.

The New Reality: Phoenix as a High-Stakes Logistics Hub

An Economy at Full Throttle

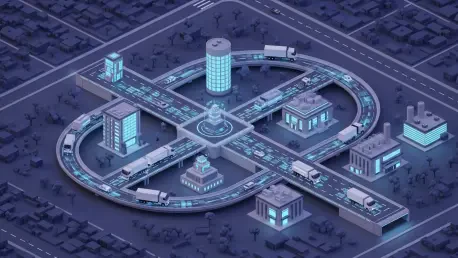

Phoenix is no longer an emerging market; it is a fully-fledged epicenter for advanced manufacturing, aerospace, healthcare innovation, and technology. This rapid economic diversification has supercharged the demand for a highly responsive and precise logistics infrastructure. As international companies establish major operations to capitalize on the region’s business-friendly environment, they bring with them complex, global supply chains that converge on the city’s airports and roadways.

This influx of industrial activity has created an environment where the velocity of commerce is relentless. From semiconductor components vital for global tech production to life-saving medical devices destined for local hospitals, the flow of goods is constant and critical. The success of these sectors depends entirely on the seamless movement of materials, making the local supply chain not just a support function but a core component of the regional economic engine.

The Critical Role of Time-Sensitive Delivery

In this high-growth environment, the concept of “on-time” delivery has been redefined. The margin for error has shrunk from days to hours, and in many cases, to mere minutes. For a semiconductor plant, a delayed shipment of a single component can halt a multi-million-dollar production line. Similarly, in the aerospace sector, a grounded aircraft awaiting a critical part represents a significant loss of revenue and operational efficiency.

The dependency on time-sensitive logistics extends across all of Phoenix’s key industries. E-commerce fulfillment centers race to meet ever-shrinking delivery windows, while healthcare networks require immediate access to surgical kits and pharmaceuticals to ensure patient care is not compromised. Consequently, airport-to-door transportation has evolved from a routine task into a mission-critical operation where speed, reliability, and precision are paramount.

Unpacking the Boom: Key Trends and Future Projections

The Perfect Storm: Converging Pressures on Phoenix’s Supply Lines

The city’s rapid expansion has created a perfect storm of logistical challenges. Increased air cargo volumes are leading to congestion at Phoenix Sky Harbor International Airport, while the urban sprawl extends delivery routes and exposes them to greater traffic-related delays. Compounding these issues are labor constraints and a rise in complex, exception-driven freight releases that require specialized handling under tight deadlines.

These pressures do not exist in isolation; they feed into one another, creating a ripple effect that can paralyze a supply chain. A flight delay, combined with congested airport access and a shortened cargo cut-off time, can make it nearly impossible for a standard logistics provider to recover. This convergence of factors is systematically exposing the vulnerabilities in supply chains that were designed for a less demanding era.

The Growth Paradox: Why Expansion Creates Unprecedented Risk

The paradox of Phoenix’s growth is that the very success driving the economy is also amplifying operational risk. As more companies compete for limited resources—from warehouse space to driver availability and airport access slots—the entire system becomes more fragile. What was once a minor inconvenience, like a documentation error or a slight traffic delay, can now escalate into a significant disruption with far-reaching consequences.

This heightened risk environment forces businesses to confront a difficult reality: the strategies that enabled their growth may not be sufficient to sustain it. Relying on logistics models that assume a smooth, predictable flow of goods is no longer a viable option. The new operational landscape in Phoenix requires a proactive approach that anticipates friction and has contingency plans built directly into the process.

When Minutes Matter: Navigating the High Cost of Delay

The Breaking Point for Traditional Logistics Models

Traditional logistics models, often built around cost efficiency and standardized processes, are reaching their breaking point in Phoenix. These systems typically lack the agility to respond to the increasing frequency of exceptions, such as late freight releases or unexpected changes in delivery requirements. When a disruption occurs, their rigid structures often prevent a swift and effective recovery, turning a manageable issue into a critical failure.

The focus on predictable, high-volume shipments leaves little room for the kind of flexible, on-demand response that is now necessary. A standard carrier may not have the resources or the authority to dispatch a dedicated vehicle for a direct-drive recovery at a moment’s notice. This inability to adapt in real time is a critical flaw in an environment where every minute of delay translates directly into lost revenue and diminished productivity.

From Disruption to Recovery: A New Operational Playbook

Navigating Phoenix’s complex logistics environment requires a new operational playbook centered on recovery and resilience. Instead of simply planning for success, businesses must actively plan for disruption. This involves developing execution models designed specifically for handling exceptions and minimizing downtime when the unexpected occurs.

This new playbook prioritizes strategies such as pre-planning for direct-drive recovery moves, which ensure a dedicated vehicle is available to retrieve urgent freight the moment it is released. It also means building redundancy into expedited ground transport networks to guarantee capacity is available when it is needed most. The focus shifts from merely managing transportation to orchestrating a sophisticated response to any potential breakdown in the supply chain.

The Rules of Engagement: Adapting to Tighter Operational Constraints

Navigating Airport Congestion and Restricted Access

The physical constraints of Phoenix’s logistics infrastructure are becoming a major hurdle. Increased cargo volumes at Sky Harbor are leading to longer wait times, earlier cut-off times for freight pickup, and more stringent access protocols for ground transportation. For businesses operating on tight schedules, these operational bottlenecks can make the difference between a successful delivery and a costly failure.

Successfully navigating this environment requires deep institutional knowledge and established relationships with airport personnel and cargo handlers. Logistics providers must be adept at maneuvering through congested terminals and coordinating pickups within rapidly shrinking windows of opportunity. Without this specialized expertise, companies risk having their critical shipments stranded on the tarmac, unable to clear the logistical logjam.

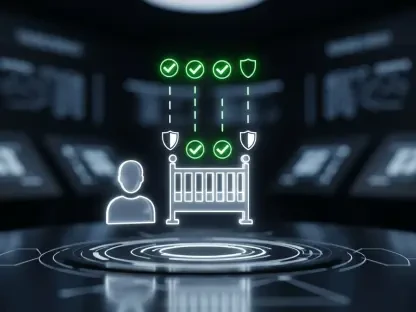

The Rising Challenge of Exception-Driven Freight

As supply chains become more complex, the volume of exception-driven freight—shipments that fall outside standard processes—is on the rise. This can include late-arriving cargo, shipments with documentation issues, or goods that require immediate, unscheduled transport. These exceptions are the true test of a logistics partner’s capability, as they demand an immediate, customized solution.

Handling exception-driven freight effectively requires a level of agility and problem-solving that commodity carriers are not equipped to provide. It necessitates a proactive communication loop, the ability to rapidly deploy assets, and the experience to resolve issues on the ground in real time. For industries like semiconductor manufacturing and aerospace, where a single shipment can be worth millions, the ability to manage these exceptions is non-negotiable.

The Resilient Supply Chain: Tomorrow’s Competitive Differentiator

Shifting from Commodity Service to Strategic Partnership

In the face of these challenges, the relationship between a business and its logistics provider must evolve. The transactional, commodity-based approach of simply hiring a carrier to move a box from point A to point B is no longer sufficient. Instead, companies must seek strategic partners who can function as an extension of their own operations, providing the expertise and resources needed to build a truly resilient supply chain.

This shift involves a deeper level of collaboration, where the logistics partner is involved in planning and strategy, not just execution. Such a partner understands the unique pressures of the client’s industry and can design customized solutions that mitigate risk and ensure continuity. The value is no longer measured solely in cost per mile but in the ability to guarantee operational uptime and protect revenue.

Building Predictability in an Unpredictable Environment

True supply chain resilience is about creating predictability in an inherently unpredictable environment. Jason Barbata, COO of Jet Delivery, emphasizes this point: “Predictability doesn’t come from avoiding disruption. It comes from being prepared for it.” This preparation involves building a logistics framework that is flexible, redundant, and capable of absorbing shocks without breaking.

Achieving this level of predictability requires a proactive mindset. It means having contingency plans in place before they are needed and partnering with a logistics provider who has a proven track record of operating under severe time and capacity constraints. Ultimately, it is this ability to deliver consistent, reliable performance, regardless of the external pressures, that will define success in the new Phoenix.

From Reaction to Readiness: A Strategic Blueprint for Success

Key Takeaways for Thriving in the New Phoenix

The analysis of Phoenix’s logistics environment has revealed several critical takeaways for businesses. It became clear that success is no longer about reaction but about readiness. Companies that thrived were those that proactively identified vulnerabilities in their supply chains and invested in contingency planning and specialized logistics partnerships.

Furthermore, the data showed that viewing time-sensitive logistics as a strategic function, rather than a cost center, provided a significant competitive advantage. This approach allowed for greater agility and ensured that even when disruptions occurred, recovery was swift and effective. This strategic alignment proved essential for maintaining production schedules and meeting customer commitments in a high-pressure market.

Final Verdict: Why Proactive Logistics is Non-Negotiable

The examination of Phoenix’s boom concluded that the escalating pressures on regional supply chains have made proactive, resilient logistics a non-negotiable component of a successful business strategy. The traditional models of transportation were found to be inadequate for the complexities of this new economic landscape.

Ultimately, the evidence demonstrated that the ability to ensure consistency and speed to market in Phoenix was directly tied to the sophistication of a company’s airport-to-door logistics capabilities. Partnering with an experienced provider was not merely an act of outsourcing transportation; it was a strategic investment in long-term operational resilience and a critical factor in securing a competitive edge.