I’m thrilled to sit down with Zainab Hussain, our esteemed retail expert and e-commerce strategist, who brings a wealth of experience in customer engagement and operations management. Today, we’re diving into the fascinating world of supply chain modernization, drawing inspiration from innovative transformations like those seen in the ice cream industry. Our conversation explores the complexities of scaling operations, the impact of cutting-edge technology on efficiency, the power of data-driven decision-making, and the importance of collaboration across teams. Join us as we uncover the strategies that help businesses stay ahead in a fast-paced market.

Can you share some insights into the biggest hurdles a growing company might face in its supply chain when expanding product lines and geographic reach?

Absolutely. When a company grows, especially with an expanding product range and new markets, the supply chain can become incredibly complex. You’re dealing with a wider variety of SKUs, which can strain existing inventory systems and forecasting methods. Adding new production facilities or distribution centers means coordinating across multiple locations, often with different processes or technologies, which can lead to inefficiencies or errors. And when you enter new geographies, you’re looking at longer lead times, diverse regulations, and even cultural differences in consumer demand. All of this can overwhelm traditional tools, making it hard to align supply with demand without a more sophisticated approach.

What factors do you think are most critical when choosing a technology partner for supply chain modernization?

It really comes down to alignment with your business needs and scalability. You want a partner whose platform offers flexibility—something that can handle unique challenges like adjusting production schedules or integrating with existing systems. It’s also about the specific capabilities: Does it provide robust forecasting tools or real-time visibility? How does it stack up against other options in terms of user-friendliness or cost? Beyond the tech, the partner’s ability to support implementation and provide ongoing training is huge. A solution is only as good as the team’s ability to use it effectively.

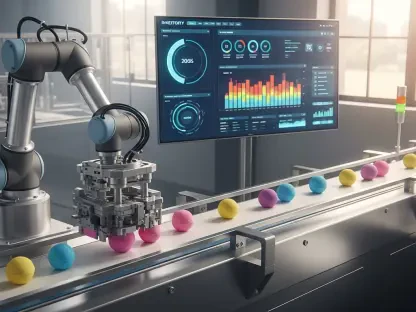

How can an end-to-end supply chain platform transform the way a business operates on a day-to-day basis?

An end-to-end platform is a game-changer because it centralizes everything. Instead of juggling multiple systems or spreadsheets, teams can access demand forecasts, inventory levels, and production schedules all in one place. This cuts down on miscommunication and speeds up decision-making. For instance, if there’s a spike in demand, you can immediately see where inventory stands and adjust production without delays. It also fosters a more proactive mindset—teams aren’t just reacting to issues; they’re anticipating them. That kind of streamlined operation can significantly boost efficiency and reduce waste.

In what ways does enhanced visibility into production capacity influence strategic planning for a company?

Having visibility into production capacity—say, seeing several weeks or months ahead—allows for much smarter planning. You can identify bottlenecks before they become problems and allocate resources more effectively. For example, if you know a certain facility will be at full capacity, you can shift production to another location well in advance. It also helps with managing seasonal peaks or new product launches, ensuring you’re not caught off guard. This kind of foresight turns reactive firefighting into strategic, data-driven decisions that save time and money.

How can modern supply chain tools help uncover opportunities for cost savings or profit growth?

Modern tools provide network-wide insights that highlight inefficiencies or untapped potential. For instance, they can analyze production costs across different facilities and suggest the most cost-effective location for a specific run based on factors like labor, energy, or proximity to distribution points. They also offer data on inventory turnover, helping to avoid overstocking or stockouts, both of which hit the bottom line. With this kind of granular insight, companies can make informed choices—whether it’s optimizing transport routes or renegotiating supplier terms—that directly impact profitability.

What role does technology play in fostering collaboration among supply chain teams?

Technology breaks down silos by creating a shared space for data and communication. When everyone—from procurement to production to logistics—works off the same platform, there’s less back-and-forth and fewer misunderstandings. Features like real-time updates or shared dashboards mean teams can see the same information at the same time, making it easier to align on goals or troubleshoot issues together. I’ve seen cases where cross-departmental collaboration led to innovative solutions, like rerouting shipments based on a last-minute forecast, simply because everyone had access to the same insights.

Can you walk us through what the implementation process for a new supply chain system might look like and some key considerations for success?

Implementation is a journey, not a switch you flip. It often starts with a phased approach—rolling out the system to one part of the business, like demand planning, before expanding to production or raw materials. Integration with existing systems, like ERP, is critical, so you’re not starting from scratch. Training is another big piece; teams need to understand not just how to use the tool but how it fits into their daily work. Regular check-ins—daily or weekly—help catch issues early and keep momentum. The key to success is flexibility; you’ve got to be ready to tweak processes as you learn what works. And of course, having a partner that offers solid support during onboarding can make all the difference.

What’s your forecast for the future of supply chain technology in driving business innovation?

I believe we’re just scratching the surface of what supply chain tech can do. Over the next few years, I expect to see even deeper integration of AI and machine learning, not just for forecasting but for real-time optimization of every link in the chain. Imagine systems that don’t just predict demand but also suggest new product ideas based on trends. Sustainability will also be a huge driver—tools that help minimize carbon footprints or optimize resource use will become standard. And as businesses become more global, technology will need to enable even greater collaboration across borders and time zones. It’s an exciting time, and companies that embrace these advancements will be the ones leading the pack.